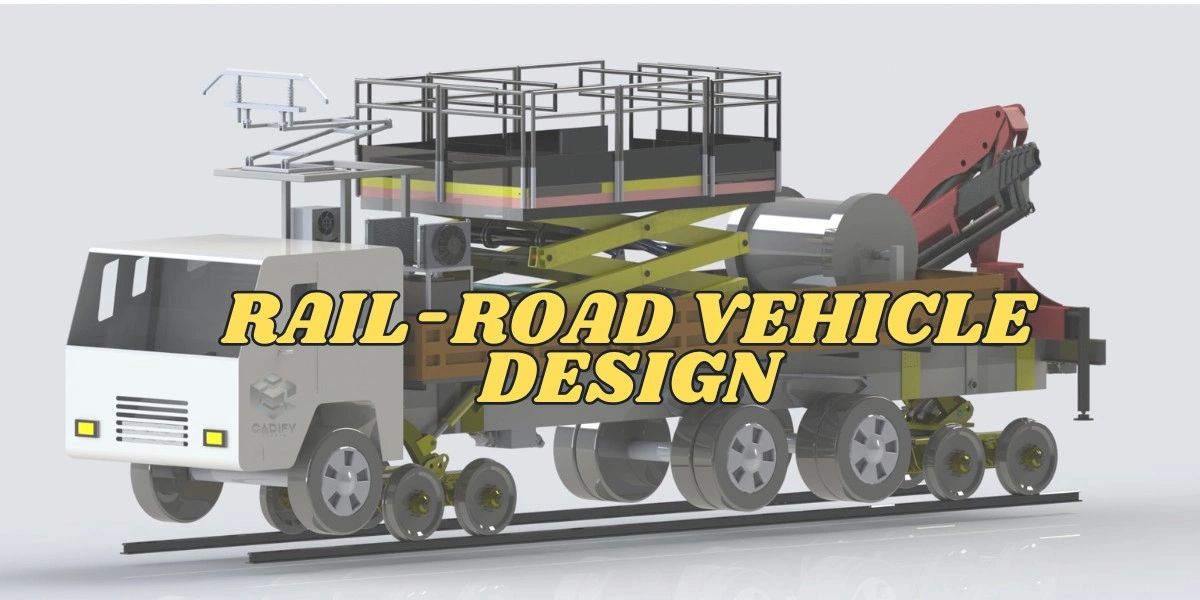

India’s railway sector is one of the largest and most complex transportation systems in the world. With rapid urbanization, industrial expansion, and a growing need for sustainable logistics, rail-road vehicle (RRVs) and advanced mechanical design services have become crucial to improving efficiency, safety, and infrastructure development.

At Cadify Studio, we specialize in rail-road vehicle design services that integrate modern CAD modeling, CAE simulations, and product engineering to create robust and high-performance railway systems. Our expertise covers everything from railway shunting and inspection car design to electrification system components and maintenance vehicles, designed specifically for India’s unique terrain and operational needs.

Understanding Rail-Road Vehicle (RRVs)

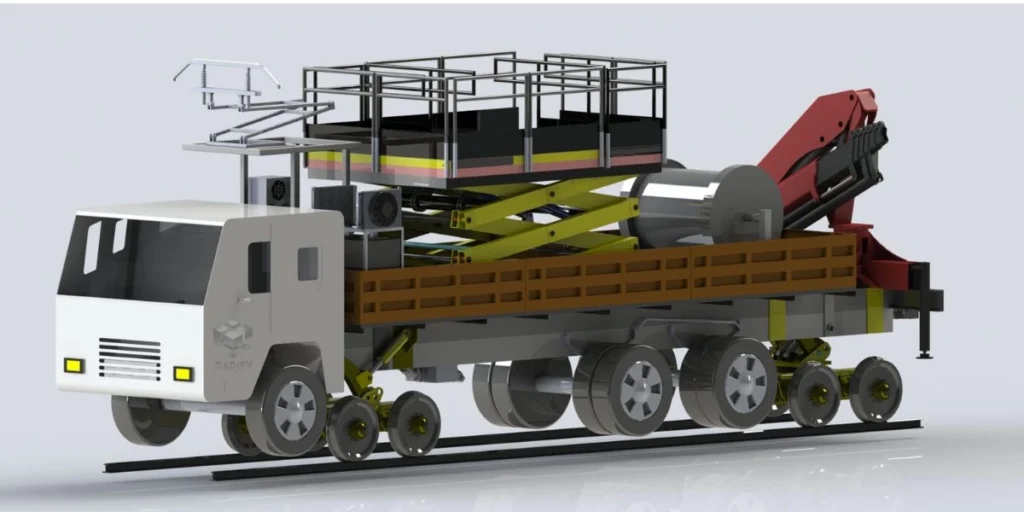

A rail-road vehicle (RRV) is a hybrid machine capable of operating on both road and rail tracks. These vehicles are extensively used for railway inspection, maintenance, and shunting operations. They offer exceptional versatility for track repairs, OHE (Overhead Equipment) maintenance and material handling, reducing downtime and improving operational efficiency.

RRVs are essential for:

- Railway electrification projects

- Track inspection and maintenance

- Emergency breakdown response

- Material transport and welding tasks

- Shunting operations in rail yards

By integrating CAD-based design and simulation, manufacturers can now ensure that RRVs meet the highest standards of durability, load capacity, and safety.

Mechanical Design for Rail Road Vehicles

Mechanical design plays a vital role in ensuring the structural integrity, performance, and reliability of railway systems. Using advanced 3D CAD tools such as CATIA, SolidWorks, and Siemens NX, engineers at Cadify Studio develop optimized models for rail shunting vehicles, inspection cars, and electrification equipment.

1. Structural Design & Frame Engineering

The chassis of a rail-road vehicle must endure high stresses during train shunting and maintenance operations. CAD software allows precise modeling of load paths, ensuring enhanced fatigue resistance and stability.

2. Suspension & Axle Systems

Shunting engines and locomotives rely heavily on advanced suspension and axle mechanisms for smooth operation. Our mechanical design ensures optimal weight distribution, wheel alignment, and traction control.

3. Thermal & Fluid Simulations

Components such as brake systems, engines, and flash butt welders undergo thermal simulations using CAE tools to test efficiency, safety, and performance in diverse weather conditions.

4. Ergonomic and Aesthetic Design

Beyond functionality, operator comfort and accessibility are integral. Our team designs intuitive cabin layouts for shunt locomotives and inspection cars, enhancing safety and ease of control.

Shunting in the Railway System: The Heart of Operations

Shunting in railway refers to the process of moving trains or rail cars within yards to rearrange, couple, or position them for further movement. It’s a crucial part of railway logistics, ensuring that wagons and engines are ready for the next journey.

Types of Shunting Operations:

- Train shunting – rearranging full trains.

- Railway shunting – moving individual wagons or coaches.

- Railroad shunting – combining multiple vehicles for freight alignment.

- Shunting engines and locomotives – dedicated small locomotives used for maneuvering rail cars.

With RRV vehicles and advanced shunting locomotives, Indian Railways can improve yard efficiency, minimize turnaround times, and enhance safety in rail operations.

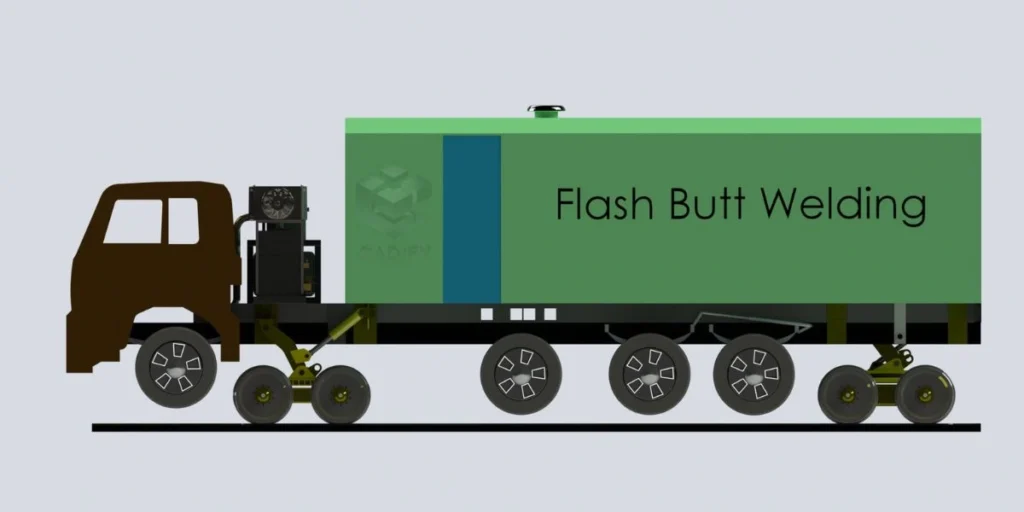

Flash Butt Welding & Electrification in Railway Engineering

⚡ Flash Butt Welding

Flash butt welding is a key technique used in railway track joining. This process involves heating rail ends using an electric current and pressing them together to form a strong, continuous joint, free from “butt flashes.”

Advantages include:

- Strong and seamless rail joints

- Long-term durability under heavy loads

- Enhanced safety and reduced track maintenance

Flash butt welders are often mounted on specialized rail-road vehicles, allowing mobile track welding for remote projects.

⚙️ Railway Electrification System in India

The railway electrification system in India is a major initiative toward sustainable mobility. Electrification reduces dependence on fossil fuels, increases train speeds, and cuts carbon emissions.

Key components include:

- Overhead Equipment (OHE): Carries electric current for train operation

- Support structures & insulators

- Traction substations and power control units

- Railway shunt systems for current management

With growing adoption of electric locomotives, train electrification has become a vital part of India’s modernization drive. Cadify Studio’s mechanical design services contribute to this progress by developing electrification tools, inspection cars, and maintenance RRVs optimized for high-voltage applications.

Railway Inspection Cars: Ensuring Safety & Precision

Railway inspection cars are specialized vehicles designed for track and overhead wire inspection. They are equipped with high-resolution cameras, OHE measuring devices, and data logging systems.

At Cadify Studio, our expertise in CAD modeling and structural analysis ensures:

- Lightweight yet durable chassis designs

- Integration of OHE monitoring equipment

- Vibration-free structure for precision inspection

- Efficient braking and suspension systems for high-speed safety

Inspection cars play a major role in maintaining India’s railway electrification network, ensuring smooth and safe train movement across the nation.

Design for Shunting Locomotives and Engines

Shunting locomotives, also known as shunt engines, are compact yet powerful machines designed for moving rail cars within yards. Our design services include:

- Cooling system and exhaust design

- Simulation of torque and traction systems

- Operator cabin design for enhanced visibility

- CAD modeling of locomotive frames and couplers

Modern shunting engines are designed with hybrid drive systems, improving fuel efficiency and reducing emissions

With increasing industrial freight, train shunting systems are evolving, requiring advanced mechanical design and simulation expertise, an area where Cadify Studio stands out.

Concrete Solutions for Railways

Concrete plays a crucial role in railway infrastructure, from sleepers and ballast retaining walls to platforms and electrification poles. CAD-driven concrete design ensures:

- Efficient load distribution analysis

- Accurate reinforcement modeling

- Compliance with Indian Railway standards

Our team provides 3D CAD drawings and simulations for concrete foundations used in railway electrification and track support systems.

Why Choose Cadify Studio for Rail-Road Vehicle Design?

At Cadify Studio, we combine technical innovation with industry experience to deliver world-class railway design solutions. Our multidisciplinary team works across mechanical, electrical, and civil domains, providing end-to-end engineering support.

🌟 Key Advantages:

- 100% data security & confidentiality

- Expertise in rail-road vehicle (RRV) design

- Experience with rail electrification systems

- Strong foundation in mechanical & structural CAD

- Integration of CAE analysis for performance testing

- Custom inspection cars and shunting locomotives

- On-time project delivery with detailed documentation

Conclusion

The future of the Indian railway industry lies in innovation, automation, and sustainability. With the expansion of railway electrification, shunting operations, and road-rail vehicle usage, precision engineering is more important than ever.

Cadify Studio continues to empower this transformation with cutting-edge CAD design, reverse engineering, and simulation expertise tailored for rail-road vehicle and mechanical design in India.

If you’re seeking a reliable partner for railway design, shunting systems, or electrification projects, Cadify Studio delivers end-to-end solutions that ensure performance, safety, and long-term reliability.

❓ Frequently Asked Questions (FAQ)

Q1. What is a Rail-Road Vehicle (RRV)?

Ans. A rail-road vehicle (RRV) is a dual-mode vehicle that can operate on both roads and railway tracks. It’s mainly used for track inspection, maintenance, and shunting in the railway industry.

Q2. What is shunting in the railway system?

Ans. Shunting means moving or rearranging rail wagons or locomotives within a yard to prepare trains for departure or maintenance. Shunting engines, or shunt locomotives, are specially designed for this purpose.

Q3. What is the role of CAD in rail vehicle design?

Ans. Computer-Aided Design (CAD) enables engineers to create accurate 3D models of railway systems, analyze performance using CAE simulations, and reduce design time while improving safety and efficiency.

Q4. What is Flash Butt Welding in Railways?

Ans. Flash butt welding is an electric rail-joining technique that fuses rail ends together to form seamless, durable joints. It ensures smoother rides and longer track life.

Q5. How does railway electrification work in India?

Ans. The railway electrification system in India uses Overhead Equipment (OHE) and traction substations to power electric trains, improving efficiency and reducing carbon emissions.

Q6. What does Cadify Studio offer for rail vehicle design?

Ans. Cadify Studio provides end-to-end mechanical design, RRV modeling, shunting system development, and electrification design solutions using advanced CAD and simulation tools.

Q7. Why is mechanical design important in the railway industry?

Ans. Mechanical design ensures the safety, reliability, and durability of every component, covering structures, suspension, braking, and inspection systems critical for railway performance.

Q8. What are railway inspection cars used for?

Ans. Railway inspection cars monitor track and electrification conditions using advanced sensors and cameras. They help detect faults early and maintain safety in the rail network.

Q9. What is OHE in Indian Railways?

Ans. OHE (Overhead Equipment) refers to the electrical system that supplies power to trains through overhead wires. It’s a vital part of the railway electrification network.

Q10. How to contact Cadify Studio for rail design services?

Ans. You can reach Cadify Studio through cadifystudio.com for rail-road vehicle design, shunting systems, and railway electrification projects tailored to your requirements.