In today’s fast-evolving technological world, robots are becoming a vital part of industries like manufacturing, healthcare, logistics, space exploration, and even home automation. At the heart of building intelligent and high-performing robots lies a powerful tool known as Computer-Aided Design (CAD). CAD helps engineers design, simulate, and build robotic systems faster, more accurately, and with greater creativity.

In this blog, we will explore how CAD plays a key role in robotics design, the tools and techniques used, and real-life applications where CAD has transformed how robots are developed.

What is CAD in Robotics Design?

CAD stands for Computer-Aided Design. It is a type of software used by engineers, designers, and manufacturers to create precise 2D and 3D models of objects. In robotics, CAD helps design mechanical parts like arms, joints, sensors, and even entire robots in a virtual environment before they are physically built.

With CAD, designers can visualize the full robotic system, view it from all angles, and simulate its movements and behavior. This digital twin allows teams to detect problems, make design changes, and test functionality—all without wasting materials or time.

Key Benefits of Using CAD in Robotics

1. 3D Modeling & Visualization

CAD allows the creation of detailed 3D models of robotic parts and systems. Engineers can rotate, zoom, and simulate how each component will move and interact. This helps understand things like range of motion and degrees of freedom (DOF), which refer to how many ways a robotic arm can move or bend.

2. Precision & Parametric Design

In robotics, even a 1 mm error can lead to failure. CAD software enables high-precision designs with accurate dimensions. Parametric modeling allows you to define relationships between parts so that changes to one part update the others automatically.

3. Simulation & Testing

Before building anything, designers can simulate how a robot will behave. CAD simulation tools can test movement, balance, collisions, and sensor response. This saves time and cost and avoids design flaws early.

4. Integration with CAM & CAE

CAD is part of a bigger design ecosystem. It integrates with:

- CAE (Computer-Aided Engineering) for testing stress, thermal, and dynamic forces.

- CAM (Computer-Aided Manufacturing) to control CNC machines or 3D printers.

This means the same CAD model can be used from design to manufacturing, reducing errors and boosting productivity.

How CAD Streamlines Robotic Development

Using CAD in robotics development saves time and ensures better results. Here’s how:

- Faster prototyping: You can quickly produce parts using 3D printing or CNC machining from CAD files.

- Team collaboration: Mechanical, electrical, and software engineers can work together using the same CAD model.

- Design iterations: Changes can be made easily, and multiple versions can be tested virtually.

- Reduced production cost: Fewer physical prototypes and fewer errors save money.Fewer physical prototypes and fewer errors save money.

Real-Life Applications of CAD in Robotics

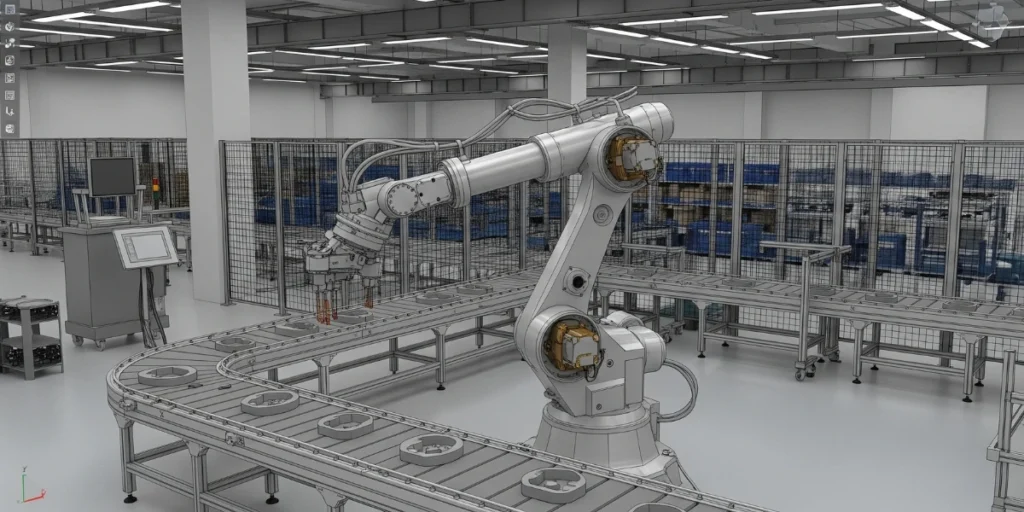

a. Industrial Automation

CAD is widely used to design robotic arms used in car manufacturing, electronics assembly, and packaging. These systems require exact movements and durability, which CAD can simulate and test.

b. Medical Robotics

Robots in surgery or diagnostics need extreme precision. CAD helps in designing tools that can work with human tissue safely and accurately.

c. Space & Rescue Robots

In hostile environments like space or disaster zones, robots must be reliable. CAD simulations can test performance under extreme conditions.

d. Consumer & Educational Robots

From robotic vacuum cleaners to learning kits for kids, CAD helps customize and build functional and safe designs that suit end-user needs.

Collaborative Robotics (Cobots) and CAD

Cobots are robots that work alongside humans. They must be safe, lightweight, and easy to interact with. CAD helps design cobots with:

- Smooth and ergonomic surfaces

- Sensors to detect human presence

- Controlled and limited movement zones

By simulating real-world interactions, engineers can ensure cobots are effective and safe in shared workspaces.

Future Trends: CAD Meets AI, AR/VR & Digital Twins

a. Artificial Intelligence (AI)

AI is now being added to CAD tools. AI can suggest design improvements, identify flaws, and help automate repetitive tasks. This means smarter, faster design processes.

b. Augmented Reality (AR) & Virtual Reality (VR)

AR and VR allow designers to interact with CAD models in 3D environments. This helps clients, designers, and teams better understand and refine robot designs.

c. Digital Twins

A digital twin is a real-time, virtual replica of a physical robot. With CAD, designers can create digital twins and use them to monitor performance and make improvements even after the robot is built.

Must-Have CAD Tools & Software for Robotics

Here are some top CAD tools for robotics design:

- SolidWorks: Popular for mechanical design with strong simulation tools.

- Solid Edge (Siemens): Great for small to medium manufacturers, combines electrical and mechanical design.

- Fusion 360: Offers cloud collaboration and integrated CAM.

- AutoCAD: Traditional 2D and 3D modeling tool.

- Spatial 3D InterOp SDK: Ensures data exchange between different CAD platforms, helping teams using different tools to collaborate.

Challenges & Considerations

While CAD offers many advantages, some challenges include:

- High learning curve: Advanced CAD tools may require training.

- Software cost: Premium software can be expensive for small teams.

- File compatibility: Not all CAD files work across platforms, but tools like Spatial InterOp help fix this.

Conclusion

CAD has become the backbone of modern robotics design. From creating 3D models and testing movement to integrating with manufacturing, CAD tools make robotic development faster, more reliable, and innovative. As technology evolves with AI, AR, and digital twins, the future of CAD in robotics looks more promising than ever.

Whether you’re designing a robotic arm for manufacturing or a companion robot for home use, investing in the right CAD tools will help turn your ideas into reality.