In today’s fast-paced engineering world, product designers and mechanical engineers constantly look for innovative tools that enhance efficiency, precision, and collaboration. One of the most exciting innovations transforming the product development cycle is Augmented Reality (AR). When combined with CAD (Computer-Aided Design), AR doesn’t just make things look futuristic—it brings designs to life, helping teams visualize, test, and improve products faster and more accurately.

What is Augmented Reality (AR)?

Augmented Reality (AR) overlays digital content—like 3D models, text, or animations—onto the physical world using devices such as smartphones, tablets, AR glasses, or headsets. Unlike Virtual Reality (VR), which creates an entirely artificial environment, AR blends real and virtual elements. This gives designers the ability to see CAD models in real-world environments, offering valuable context and enhanced understanding.

Why Use AR in Product Design?

The combination of Augmented Reality and product design is a game-changer. Here’s why:

- Real-time visualization of CAD models in physical spaces

- Improved collaboration among teams and stakeholders

- Early detection of design flaws and space constraints

Enhanced communication with clients through immersive presentations

Key Topics Explained in This Blog:

- Benefits of AR in CAD Visualization

- How AR Transforms 2D to 3D Understanding

- Real-world Applications in Product Design

- Challenges and Solutions with AR in Engineering

- Future Trends in AR + CAD

- How CADify Studio Can Help

1. Benefits of Augmented Reality in CAD Visualization

Traditionally, CAD models were viewed on a flat screen, making it difficult to fully grasp their form, scale, and spatial fit. With AR, that changes completely. AR allows engineers and designers to view interactive 3D models right in their physical environment.

Key benefits include:

- Enhanced spatial understanding of designs

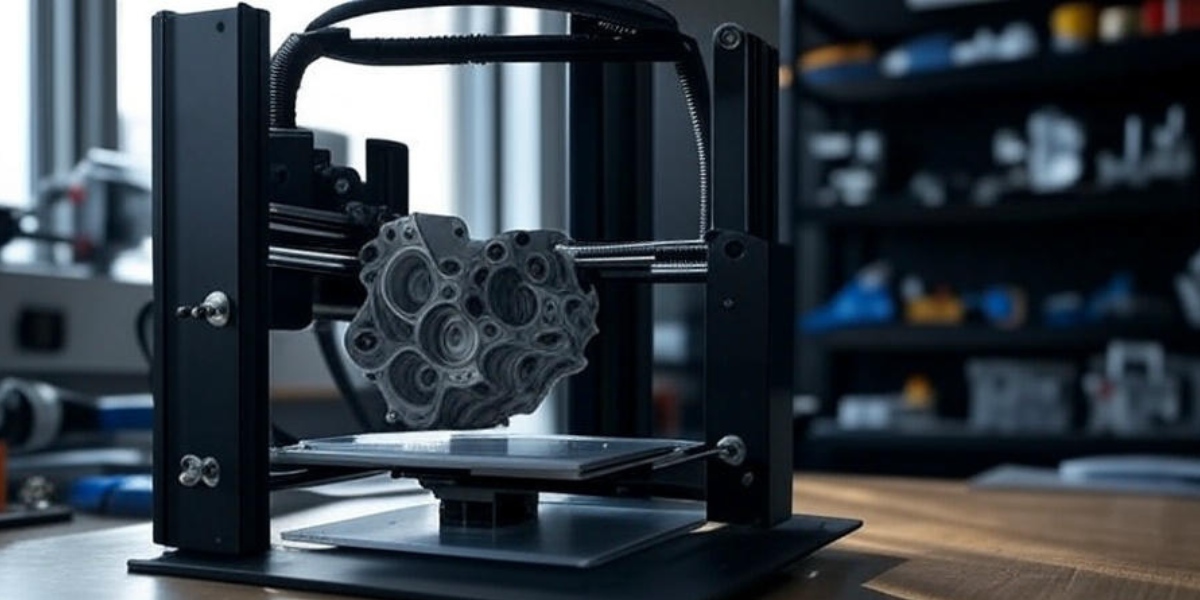

- Quick and low-cost iterations without physical prototypes

- Reduced design errors by up to 30%

- Intuitive navigation using gestures, voice commands, or touchscreens

- Collaborative real-time feedback from remote teams

2. Transforming 2D CAD Drawings into Immersive 3D Models

Engineers often start with 2D drawings in CAD software. With AR, these drawings can be transformed into real-scale 3D models that you can walk around, inspect, and interact with. This helps in:

- Understanding the real-world scale and how parts fit together

- Spotting design flaws that may not be visible on screen

- Speeding up the decision-making process

Imagine viewing a machine assembly directly on your factory floor, with all components virtually in place. AR lets you do that.

3. Real-World Applications of AR in Product Design

Augmented Reality in product design is being used across various stages of the design lifecycle:

a. Early Concept Validation

Before building a prototype, designers can visualize the product in real space using AR. This is called pretotyping—testing an idea quickly and cheaply.

b. Digital Twin Simulations

A digital twin is a virtual replica of a physical object. With AR, this digital twin can be tested in different conditions, reducing the need for physical testing.

c. Team Collaboration

With AR headsets or mobile devices, remote teams can view the same model and give input in real time. No need for constant emails or design meetings.

d. Assembly Guidance

AR provides step-by-step instructions during complex product assembly. This reduces human error and speeds up production.

e. Client Presentations

Instead of showing static images, AR allows clients to experience products in 3D, increasing understanding and confidence in the design.

4. Overcoming Challenges in AR for CAD

While AR is powerful, it comes with some challenges:

- CAD File Compatibility: Not all CAD file types are optimized for AR. Files like FBX or GLTF are better for AR than STL or STEP.

- Hardware Requirements: High-quality AR experiences need capable devices and sometimes advanced headsets.

- Training: Engineers may need basic training to use AR tools effectively.

- Data Optimization: AR models must be lightweight to run smoothly, requiring polygon reduction and texture optimization.

- Solution: Platforms like Unity, combined with optimized CAD conversion tools, help overcome these challenges.Platforms like Unity, combined with optimized CAD conversion tools, help overcome these challenges.

Imagine viewing a machine assembly directly on your factory floor, with all components virtually in place. AR lets you do that.

5. The Future of AR in CAD and Engineering

The future of Augmented Reality in engineering and product design is promising. Here are some trends to watch:

- AI-integrated AR that predicts design flaws automatically

- Haptic feedback allowing users to feel surfaces and textures

- Cloud-based AR collaboration platforms

- Full-scale AR prototypes accessible via smartphones

These technologies will further shorten design cycles, reduce errors, and enable rapid innovation.

6. How CADify Studio Can Help

If you’re looking to adopt AR for CAD visualization in your product design process, CADify Studio is here to help.

We offer:

- AR-ready conversion of your CAD files

- Custom AR solutions for product design, prototyping, and client demos

- Interactive AR guides for assembly and training

- Expert consultation on integrating AR into your workflow

Conclusion

Augmented Reality is not just a trend—it’s a powerful tool that’s enhancing CAD visualization and revolutionizing how products are designed, tested, and presented. From transforming 2D sketches into immersive 3D models to improving team collaboration and customer engagement, the benefits of AR in product design are vast.

CADify Studio can help in this journey with end-to-end support for integrating AR into your design pipeline.