In the era of digital manufacturing, 3D printing and CAD modeling have emerged as the driving forces behind innovation, allowing businesses to transform ideas into tangible results with unprecedented speed and precision. Combined with CAD/CAM solutions, these technologies enable advanced simulations, streamlined workflows, and efficient production methods. From rapid prototyping to sustainable production, the synergy between 3D printing, CAD design, and CAD/CAM tools is revolutionizing industries worldwide, setting new benchmarks for productivity and creativity.

Challenges in Design and Manufacturing

Modern industries face several pain points that hinder their design and production processes:

- Time and Cost Constraints: Delivering projects on time without inflating budgets.

- Complex Geometries: Designing intricate components that require extreme precision.

- Sustainability Goals: Adopting eco-friendly practices while minimizing material waste.

- Customization Demands: Addressing the growing need for personalized solutions at scale.

The integration of CAD modeling, 3D printing, and CAD/CAM solutions directly addresses these challenges by improving design accuracy, reducing waste, and enhancing production speed.

The Role of CAD Modeling in 3D Printing and Manufacturing

At the heart of modern manufacturing, CAD modeling lays the foundation for success, ensuring:

- Precision in Design: Detailed 2D and 3D models that accommodate intricate geometries.

- Simulation and Validation: Using advanced tools like FEA and CFD to test designs.

- Seamless Prototyping: Exporting CAD files to 3D printing systems for rapid iterations.

- Efficient Collaboration: Cloud-based tools that enable teams to work on shared models effortlessly.

The integration of CAD CAM and additive manufacturing enhances innovation while reducing time-to-market, ensuring businesses stay ahead of the competition.

Top Benefits of Combining 3D Printing with CAD/CAM Solutions

The fusion of 3D printing and CAD/CAM tools provides unparalleled advantages:

- Accelerated Prototyping: Transform digital models into physical prototypes in hours.

- Reduced Waste: Adopt sustainable CAD design principles with optimized material usage.

- Customization at Scale: Cater to personalized demands while maintaining efficiency.

- Automated Workflows: Generate precise toolpaths with minimal manual intervention.

- Enhanced Innovation: Overcome limitations with advanced designs enabled by CAD modeling for 3D printing.

Applications Across Industries

The impact of 3D printing and CAD modeling is felt across diverse sectors:

- Aerospace and Defense: Lightweight, high-strength components for aircraft and satellites.

- Automotive: Designing and producing vehicle parts with advanced CAD/CAM solutions.

- Medical Devices: Custom implants, surgical tools, and prosthetics made with precision.

- Consumer Products: Prototyping and manufacturing personalized goods for niche markets.

- Architecture: Creating intricate scale models and CAD designs for manufacturing complex structures.

Why Choose Cadify Studio?

At Cadify Studio, we bring your ideas to life with a perfect blend of 3D printing, CAD modeling, and CAD/CAM solutions.

- Expert Team: Over a decade of experience in CAD CAM and additive manufacturing.

- Advanced CAD Software: Expertise in tools like SolidWorks, Fusion 360, CATIA, and more.

- Tailored Workflows: Customizable solutions to suit your unique project needs.

- Sustainability Focus: Pioneering eco-friendly practices in digital manufacturing trends.

When you partner with Cadify Studio, you’re choosing a team dedicated to innovation, precision, and results.

Conclusion

The combination of 3D printing and CAD design is transforming industries by enabling faster, more sustainable, and cost-effective production processes. At Cadify Studio, we’re here to empower your projects with cutting-edge technology and unmatched expertise.

Contact us today to explore how our CAD solutions for industries can elevate your ideas and bring them to life.

Frequently Asked Questions

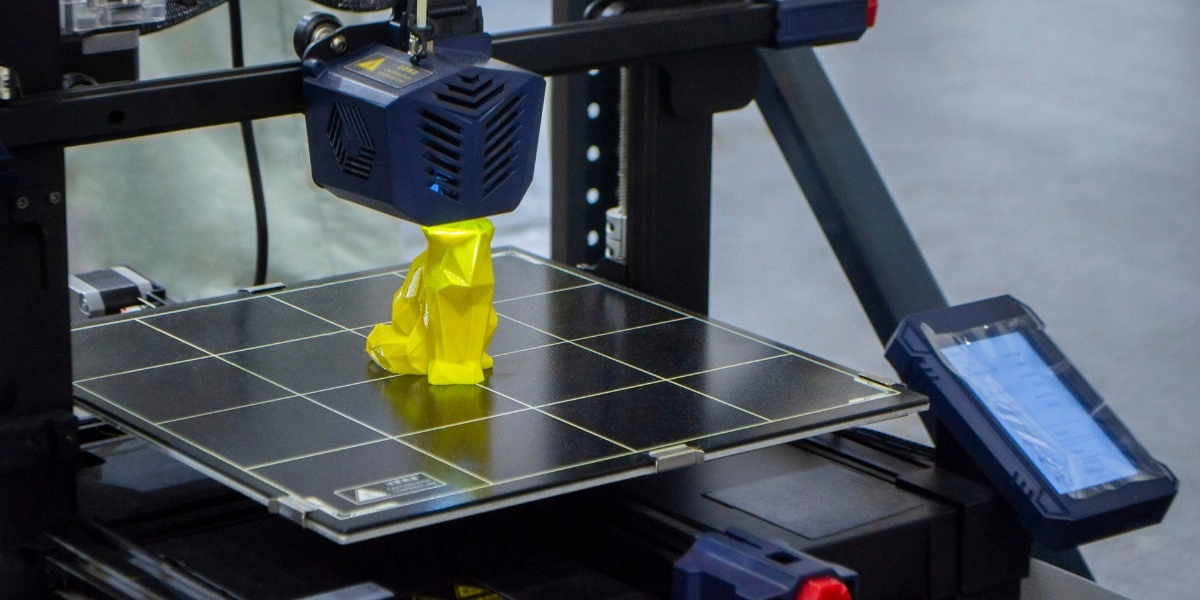

Ans. CAD stands for “Computer-Aided Design,” which is a software program used to create digital 3D models of objects on a computer, while 3D printing is the process of taking that digital design and physically manufacturing a tangible object by layering material layer by layer, essentially “printing” a real-world version of the CAD model. Together, these technologies streamline the process of turning ideas into physical prototypes or finished products.

Ans. To 3D print a CAD design, you first need to create your design using a CAD software like Fusion 360, SketchUp, or Tinkercad. Then export the model in a compatible file format (usually STL). Finally, use slicing software on your 3D printer to convert the model into layer instructions that the printer can understand and print the object layer by layer. This process bridges the gap between digital design and physical creation.

Ans. 3D CAD design refers to the process of creating three-dimensional digital models of objects using computer-aided design (CAD) software. This allows designers and engineers to visualize and manipulate designs in a virtual space before physical production, encompassing features like length, width, and depth of an object in detail.

Ans. 3D printing and design is the process of using 3D modeling software to create a digital model of an object and then using a 3D printer to build a physical copy of that object. This approach is widely used for prototyping, custom manufacturing, and creative applications across industries.

Ans. AutoCAD 3D printing is the process of using AutoCAD software to design and create 3D models that can be printed using a 3D printer. AutoCAD offers precision and flexibility in creating complex geometries, which can be exported in formats like STL and used to manufacture physical objects with a 3D printer.

Ans. 3D printing in CAD refers to the process of using Computer-Aided Design (CAD) software to create a digital 3D model that can be subsequently converted into a physical object through a 3D printer. CAD ensures accuracy and design flexibility, making it a critical step in the 3D printing workflow.

Ans. CAD (Computer-Aided Design) is a digital design process used to create and refine models of objects, while 3D printing is a manufacturing process that transforms those designs into physical objects. Simply put, CAD focuses on designing components, while 3D printing focuses on making them.

Ans. CAD (Computer-Aided Design) software is used to create detailed 3D digital models, which are then converted into instructions that a 3D printer can read. The printer uses this data to build the object layer by layer. This combination ensures seamless design-to-production workflows, enabling accurate prototyping and efficient manufacturing.